How to Seal an Aluminum Boat

To seal an aluminum boat, first clean the surface and then apply a marine-grade sealant to all leaks and seams. Ensure the sealant is appropriate for aluminum and water exposure before application.

Owning an aluminum boat comes with the responsibility of regular maintenance to ensure its longevity and safety. Among the various tasks, sealing the boat stands out as a critical measure to prevent leaks and potential damage. A well-sealed aluminum boat not only performs better but also saves you from costly repairs in the long run.

Sealing an aluminum boat is a DIY-friendly process, but it requires attention to detail and the right materials. Using a high-quality, aluminum-compatible sealant is crucial in creating a durable barrier against water. A thorough inspection of the boat’s surface to identify problem areas is necessary before you begin the sealing process. Understanding the right techniques can make the task efficient and effective, helping to prolong the life of your boat and ensure many trouble-free hours on the water.

Credit: m.youtube.com

Sealing An Aluminum Boat: The Essentials

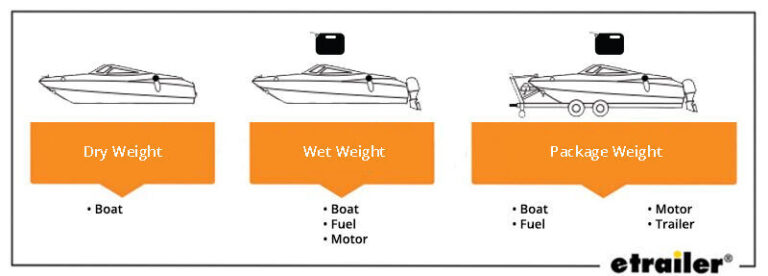

Sealing your aluminum boat is key to maintaining its durability and longevity. Water can cause damage if it enters through unsealed seams or rivets. Over time, this damage can lead to leaks and more serious issues. Sealing helps to prevent water from entering and protects the boat’s integrity.

| Material | Description | Quantity |

|---|---|---|

| Marine Sealant | Waterproof and flexible | Depends on boat size |

| Putty Knife | For applying sealant | 1 |

| Cleaning Solvent | To prepare surfaces | 1 bottle |

| Sandpaper | For smoothing areas | Multiple grits |

| Cloth Rag | For wiping off residue | Several |

| Gloves | Protect hands during work | 1 pair |

Credit: www.boatlife.com

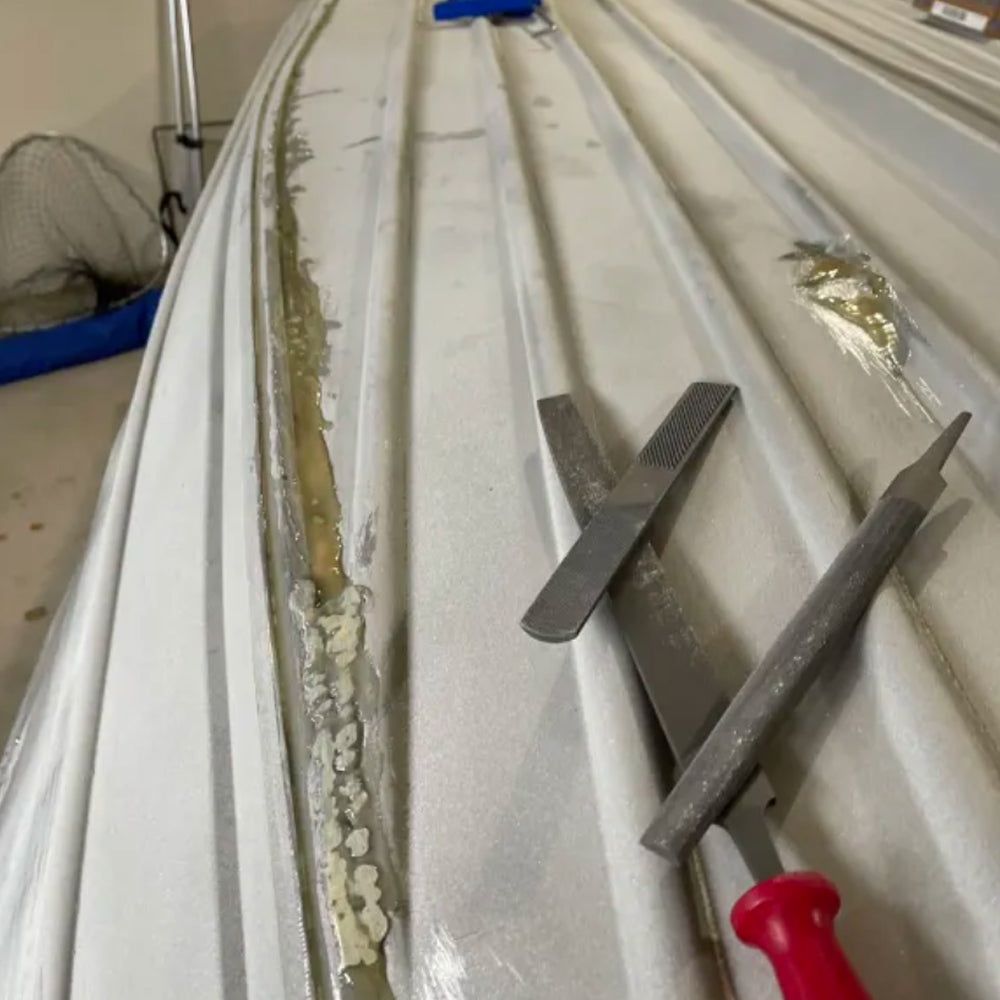

Preparing The Aluminum Surface

Clean your aluminum boat before you start. Dust, grime, or grease will prevent a good seal. Use soapy water and a sponge or brush to scrub the surface well. Rinse the boat with clean water after cleaning. Allow it to dry.

Next, focus on sanding the aluminum surface. This step ensures the sealant adheres properly. Use fine-grit sandpaper and sand the boat evenly. Wipe away all dust with a clean cloth. Your boat is now ready for sealing.

Choosing The Right Sealant

Choosing the right sealant is crucial for repairing an aluminum boat. Various types of aluminum sealants are available, each designed for specific conditions and applications. Look for a sealant offering high resistance to water and excellent adhesion to aluminum surfaces. Durability is also vital, as it determines how often you’ll need to reapply the product. Some sealants excel in flexibility, an important feature that allows the material to expand and contract without breaking.

Popular choices include polyurethane and silicone-based sealants. Polyurethane is known for its strong bonding capabilities, while silicone offers superior water resistance. Review the product’s cure time to ensure it fits your repair schedule.

The Sealing Process Step By Step

Seal your aluminum boat with great care to ensure no leaks. Prepare the surface before applying any sealant. Use fine-grit sandpaper for a clean, rough surface. Clean dust and debris off the boat’s surface. Choose a good-quality marine sealant designed for aluminum. Following the manufacturer’s instructions is key.

Apply sealant evenly across leaks or seams, using a caulking gun. Sealant spread should be smooth to prevent air bubbles. A spatula can help create an even layer. Don’t rush the process. Let the sealant cure for the recommended time. It ensures a waterproof barrier. Double-check coverage to confirm no spot is missed. This diligence promises a durable and robust seal for your boat.

Curing Time And Post-sealant Care

Proper curing of sealant is vital to ensure your aluminum boat remains watertight. Expect the sealant to fully set within 24 to 72 hours. During this period, keep the boat dry and avoid disturbance. After curing, regular inspections can extend the life of the seal.

Maintaining the seal requires periodic checks, especially before prolonged use or after exposure to harsh conditions. Clean the sealed areas with a gentle, non-abrasive cleaner to prevent buildup that could damage the sealant. Reapply sealant as needed to address any signs of wear or damage.

Credit: www.totalboat.com

Common Pitfalls To Avoid

Preparing the aluminum boat surface is vital. Sanding removes old paint and creates a rough area for sealant. Clean with a degreaser to remove oil and dirt afterward. Skipping these steps leads to poor sealant bonding. Always work in dry and moderate temperatures; moisture and cold are your enemies here.

Never apply sealant in rain or extreme cold. The right weather makes the sealant stick better. Check the forecast for dry, warm days ahead. High humidity and low temperatures can ruin the sealant’s effectiveness. Ensure the work area is well-ventilated and out of direct sunlight as the heat may cause the sealant to dry too fast.

Frequently Asked Questions On How To Seal An Aluminum Boat

What Is The Best Thing To Seal An Aluminum Boat With?

Use marine-grade epoxy resin to effectively seal an aluminum boat. It provides a hard, water-resistant finish that withstands harsh marine environments.

How Do I Stop My Aluminum Boat From Leaking?

Identify the leak source on your aluminum boat. Clean the area around the leak thoroughly. Apply a waterproof epoxy or marine-grade sealant directly to the hole or crack. Allow it to cure fully according to the product instructions. Test for water tightness after repair.

Does Flex Seal Work On Aluminum Boat?

Yes, Flex Seal effectively seals leaks and cracks in aluminum boats. It’s a popular choice for quick and durable repairs.

What Do You Use To Seal Aluminum?

To seal aluminum, use epoxy resin, urethane, silicone, acrylic, or latex-based paints. These sealants provide durable, weather-resistant protection.

Conclusion

Sealing your aluminum boat is essential for longevity and performance. With the right materials and techniques, it’s a manageable task. Remember to let each layer cure fully for best results. Regular maintenance ensures your vessel stays in top condition, ready for any adventure.

Safe boating!