How to Drill Fiberglass Without Cracking

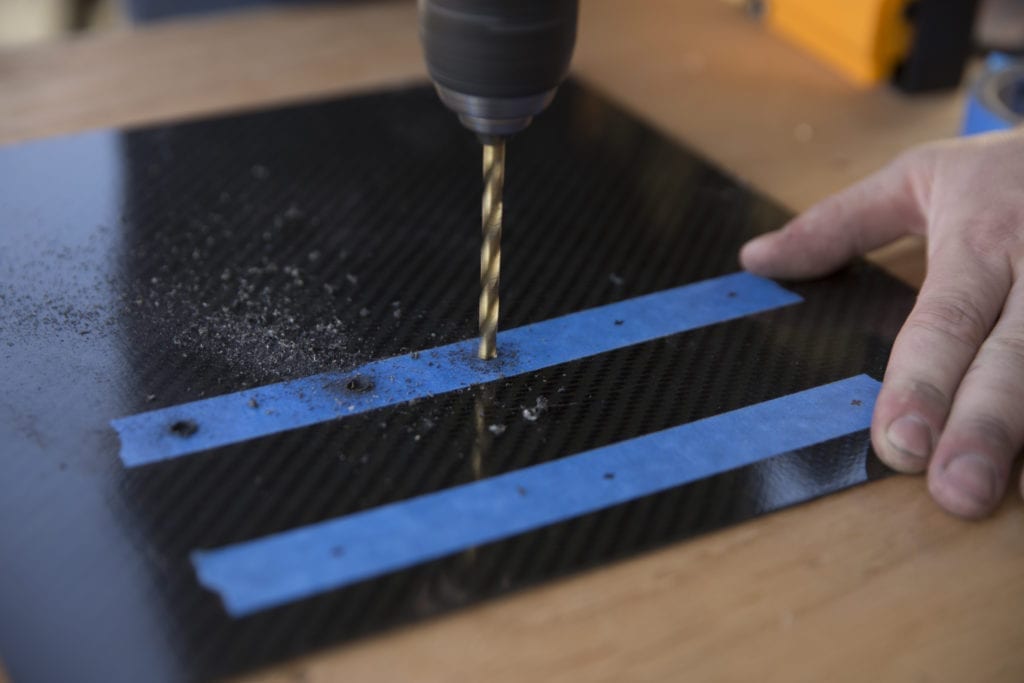

To drill fiberglass without cracking, use a center punch to create a small indent on your mark before drilling, and set your drill to the reverse position. By following these steps, you can break through the gelcoat layer without causing any cracks or chips.

Fiberglass can be a delicate material to work with, but with proper technique and equipment, you can successfully drill into it without any damage. By taking the necessary precautions and using the right tools, you can ensure a clean and precise hole in your fiberglass surface.

Whether you are working on a boat, a fiberglass enclosure, or any other fiberglass structure, following these guidelines will help you avoid cracking the material and achieve the desired results.

Preventing Cracks When Drilling Fiberglass

When drilling fiberglass, it is important to use the right drill bit to prevent cracking. Chamfering pilot holes with a countersink bit can also help minimize the risk of cracks. Similarly, countersinking all fastener holes enhances the durability of the seal. To cut a hole in fiberglass, you can use a fine-toothed hole saw, pre-drilling a small hole in the center and then carefully cutting out the area. Before drilling, creating a small indent with a center punch can prevent the bit from skipping and help in breaking through the gelcoat layer without cracking or chipping.

Methods For Cutting Holes In Fiberglass

When it comes to drilling holes in fiberglass, using a fine-toothed hole saw is the easiest and least complex method. Start by laying out the size and location of the cutout, then pre-drill a small hole in the center within the cutout area for the hole saw to start. When cutting, make sure to set your drill to the reverse position to prevent cracking or chipping. This practice allows you to break through the gelcoat layer without damaging the fiberglass. Additionally, before drilling, use a center punch to create a small indent in the center of your mark to keep the drill in place and prevent slipping. By following these steps and being cautious while cutting, you can successfully drill fiberglass without cracking it.Tips And Techniques For Drilling Fiberglass

When it comes to drilling fiberglass without cracking, there are a few tips and techniques to keep in mind. Before drilling, use a center punch to create a small indent, set your drill to reverse, and start drilling to break through the gelcoat layer without any cracks or chipping.

Before drilling into fiberglass, it’s important to create a small indent in the center of your mark using a center punch. This will help keep the drill in place and prevent the bit from skipping. Additionally, setting your drill to the reverse position can also be beneficial. By doing this, you can break through the gelcoat layer without cracking or chipping. When it comes to the drill bit itself, it’s recommended to use a sharp drill at a high speed. This will help ensure a clean and smooth hole without causing damage to the fiberglass. It’s also worth noting that chamfering pilot holes with a countersink bit can prevent screws from fracturing the gelcoat layer. Overall, following these tips and techniques can help you drill fiberglass without cracking.

Credit: www.emercytools.com

Preventative Measures For Fiberglass Crack Prevention

When drilling fiberglass, it’s crucial to use epoxy putty as a preventive measure for crack prevention. Apply gentle pressure while sanding to achieve a smooth finish without causing cracks. The use of a center punch before drilling helps keep the bit in place and prevents skipping. Additionally, using a reverse drill position can help break through the gelcoat layer without causing cracks or chips.

Additional Resources For Drilling Fiberglass

- JerryRigged: Check out this forum for discussions and tips on drilling fiberglass correctly.

- The Hull Truth: Find advice from fellow boaters on drilling and screwing into fiberglass without chipping.

If you’re wondering what kind of drill bit to use for fiberglass, consider SHOCKWAVE Lineman’s Fiberglass Drill Bits by Milwaukee Tool.

To prevent cracks and chipping while drilling fiberglass, consider these tips:

- Chamfer pilot holes with a countersink bit to avoid fracturing the gelcoat layer.

- Countersink all fastener holes to enhance the durability of the seal.

- Before drilling, create a small indent with a center punch to keep the drill in place.

- Set your drill to the reverse position and start drilling to break through the gelcoat layer without cracks or chips.

For a comprehensive guide on using the right fastener for your fiberglass project, check out BoatUS.

If you need to cut a hole in fiberglass, follow these steps:

- Layout the size and location of the cutout.

- Pre-drill a small hole in the center of the cutout area for the hole saw to start.

- Carefully cut out the area to be removed using a fine-toothed hole saw.

Remember to practice caution and follow these guidelines to successfully drill and work with fiberglass without cracking or damaging the material.

Credit: www.elevatedmaterials.com

Credit: www.quora.com

Frequently Asked Questions On How To Drill Fiberglass Without Cracking

What Kind Of Drill Bit Do You Use For Fiberglass?

When drilling fiberglass, use a carbide-tipped or diamond-coated drill bit to prevent cracking.

Can You Drill A Hole Through Fiberglass?

Yes, you can drill a hole through fiberglass. Use a sharp drill at high speed and carefully apply pressure to prevent cracking or chipping of the fiberglass. Pre-drill a small hole in the center of your mark using a center punch to keep the drill in place.

Can I Screw Directly Into Fiberglass?

Yes, you can screw directly into fiberglass, but you must first chamfer pilot holes with a countersink bit to prevent screws from fracturing the gelcoat layer. Additionally, countersink all fastener holes to enhance the durability of the seal.

What Is The Best Way To Cut A Hole In Fiberglass?

The best way to cut a hole in fiberglass is to use a fine-toothed hole saw. Start by marking the hole’s size and location, pre-drill a small hole in the center, and then carefully cut out the area with the hole saw.

Avoid cracking by taking it slow and steady.

Conclusion

To ensure a successful drilling process for fiberglass, it is crucial to follow the right techniques and use the appropriate tools. By implementing the tips discussed you can effectively drill fiberglass without the risk of cracking or damaging the material.

Remember to exercise caution, maintain steady control, and utilize sharp drill bits for optimal results. With these insights, you can confidently tackle drilling fiberglass projects with precision and finesse.